Of course, there are packages you can buy to help you with that. Similarly, if you choose to create an optimized layout for parts cut from sheet goods, you must do that manually.

For example, if you’re using CAD for woodworking after finishing the design, you must go through your drawings and pull off your cut list or your part list. They do not provide critical woodworking reports. While CAD programs generally do an excellent job creating shop drawings with dimensions. There is one significant setback for those who persist in pursuing the marketeer’s packaging of CAD for woodworking.

#Woodwork cad software

Generally, people trying to learn to use CAD software find that they can conquer the task in two dimensions but have difficulty moving into that third dimension. Then you use the tools to push or pull that rectangle into a tenon or hole. If you want to place a hole in an object or add a tenon on a board edge, you draw a rectangle locating it as needed.

One particularly egregious procedure in CAD software marketed to woodworkers is that of extruding. This is very difficult to keep straight in your mind One might guess that most icons rarely get used, some of which are combined with other icons. In fact, we don’t hold that distinction in the physical woodworking world.Īnother thing you’ll notice when you glance at a CAD software user interface is that there are many small icons, each linking to a function. You might think of a cabinet carcass as one layer and the face frame as another. You can choose where the objects will be placed by displaying or hiding layers. Then there is the concept of layers by which you can slice up the design into collections of related objects. And using the cutting tool, you can create as many sides as are necessary for your design. Generally, a board has two surfaces and four sides. For woodworkers, it’s much easier to take that basic building block of woodworking design and call it what it is.

#Woodwork cad how to

When using CAD, or perhaps watching a video explaining how to use CAD, you’ll notice that terms like geometry, vector surfaces, and vertices are used to describe the design elements. It’s much easier to use the words “height,” “width,” and “depth” and call them left-right, front-back, bottom-top.

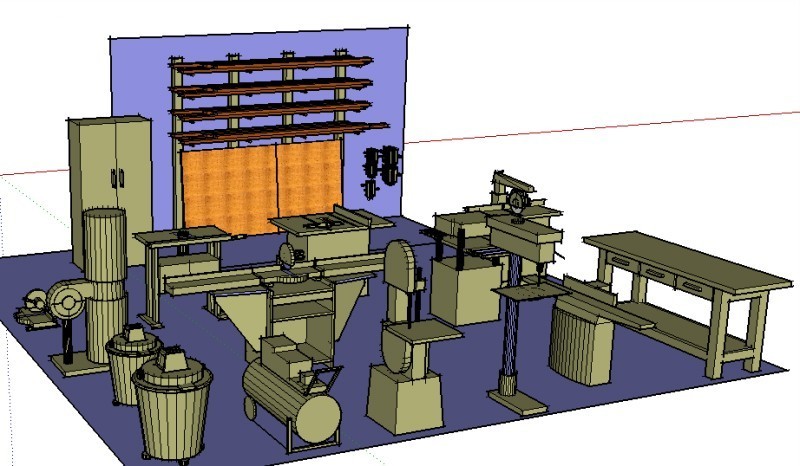

The first is to notice that the CAD program to work in three-dimensional space uses the timeless mathematical approach of X, Y, and Z. To see why, consider the terminology, toolset, and approaches of traditional CAD. Instead, they are cumbersome and do not facilitate the woodworking design task. This is not to say that CAD programs are not very useful for design. The CAD program uses concepts and approaches conceived in the metalworking industry several decades ago. You should carefully consider using CAD programs marketed as a woodworking design tool. What is a better option is woodworking-specific cad software. But still, it too can disappoint the user. Of course, software CAD means computer-aided (or assisted) design. CAD companies are out to sell woodworkers CAD software.

No female cads? The synonyms for cad include scoundrel, rascal, good-for-nothing, cheat, fraudster, and trickster, among others. “You cad you.” What is a Cad anyway? One definition is “a man who behaves dishonorably, especially toward a woman.” Hmmm.

0 kommentar(er)

0 kommentar(er)